EL Current Limiting Fuses

ELS Full Range Current-Limiting Fuse |

|

GENERALThe Cooper Power Systems ELS Full Range Current-Limiting Fuse is designed especially for use with EL Bay-O-Net Fuse Holders. |

The fuse combines the ease of operation of the Bay-O-Net Fuse Holder with the energy-limiting protection of the full range current-limiting fuse. ELS fuses are used for protecting transformers filled with transformer oil or an approved equivalent and for circuit protection in sectionalizing devices. Quiet, safe operating characteristics are ideal for installations where flame discharge and loud operation are undesirable. Since the fuse is submersible, it can be used with smaller clearances, shorter creep paths, and simpler loadbreak mechanisms. Submersible installations eliminate damage from erosion and chemical changes from weathering.

INSTALLATION

No special tools are required. The fuse is threaded by hand onto the inner holder of an EL Bay-O-Net Fuse Holder.

ELST Full Range Current-Limiting Fuse

|

|

GENERALThe RTE® ELST full range current-limiting tandem fuse assembly is designed for use in padmount switchgear filled with transformer oil or approved equivalent. It may also be used in large padmount transformers. |

The fuse’s highly efficient current limiting section reduces the effects of high fault current stresses on upstream and downstream apparatus because it limits energy let through during high current fault clearing. The expulsion section protects the current-limiting fuse from system voltage following a high current fault on the system.The ELST fuse assembly is mechanically interchangeable with the K-MATE™ SL assembly and with other manufacturers’ current limiting tandem fuse assemblies. NOTE: Only components of identical manufacture and ratings should be assembled together and installed in three-phase applications. The “E” rated fuse has time-current characteristics that are easier to coordinate with existing protective devices, such as boric acid fuses, reclosers and power fuses.

ELST & ELSG Fuse Holders |

|

GENERALThe RTE® ELST fuse holder is a non-load break device used to mount RTE ELST (Section 240-75) currentlimiting fuses in oil-filled distribution apparatus. The handle assembly and the upper contact cap guide finders provide the ease of hotstick operation for fuse removal for inspection and/or replacement. INSTALLATIONAn outer flange is welded to the apparatus sidewall. Internally a fuse holder is bolted to the flange. |

gasket insures a tight seal from the environment.

ELSP Current-Limiting BackUp Fuse |

|

GENERALThe Cooper Power Systems ELSP Current-limiting Backup Fuse is used in series with low current primary protection devices such as a Bay-O-Net Fuse or MagneX® Interrupter.

|

Its minimum interrupting rating is coordinated with that of a low current interrupter to avoid undesirable low

current operation; yet its maximum interrupting rating will clear the highest fault currents likely to occur. Higher

continuous current ratings can be achieved by connecting two fuses in parallel.

APPLICATION

The ELSP fuse is used in transformers to protect and isolate faulted equipment. When connected in series with a low current primary protection device, the fuse becomes an element of a two part protection system that gives a full range of fault protection.

This two-part system provides low current protection with the replaceable expulsion fuse or resettable MagneX

Interrupter, and it adds the energy limiting protection of a current-limiting fuse. Together, they coordinate easily

with upstream and downstream devices.

INSTALLATION

No special tools are required. The fuse is liquid immersed, mounted as near as possible to the incoming primary

bushing to which it is connected. Normal liquid dielectric clearances should be used.

ELG Current-Limiting Power Fuse |

|

GENERALCooper Power Systems' ELG power fuse is a full-range general purpose current-limiting fuse that provides |

The ELG fuse is designed to meet the needs of stringent industrial and utility applications. The high interrupting capacity and reduced let-through energy provide for excellent equipment protection. ELG fuses are used to protect power transformers, feeders and other equipment that can benefit from their energy-limiting properties.

Noiseless operation and the lack of expulsion by-products make them ideal for indoor application in confined spaces. They fit in a standard power fuse mountings and are suitable for indoor and outdoor fuse installations. The "E" rated fuses have time-current characteristics that coordinate easily with other upstream and downstream protective devices.

INSTALLATION

No special tools are required. The ELG fuse is designed for indoor and outdoor mounting in industry standard in-air clip mountings and fused disconnect switches. See installation and Instruction Sheet S240-80-1 and the fuse mounting manufacturer's instructions for details.

ELG Current-Limiting Power Fuse |

|

||||

GENERALThe Cooper Power Systems ELSG fullrange current-limiting fuse is designed for use in pad-mounted switchgear filled with Envirotemp FR3 fluid, mineraloil or approved equivalent. It may also be used to protect power transformers, feeders and other equipment that can benefit from its energy-limiting properties. The fuse provides consistent clearing of low currents as well as reliable high speed interruption of high magnitude short circuit currents. |

Its current-limiting capability limits both peak current magnitude and fault duration, thus limiting the let through energy. ELSG fuses have both the low current and high current clearing sections in one housing. This eliminates expulsion by-products discharging into the oil when the fuse operates. Concerns associated with miscoordination of

Also, field testing the current-limiting section when the expulsion section operates is also eliminated. The E-rated ELSG fuses have time-current characteristics that coordinate easily with other upstream and downstream protective devices. The MSLF version of the ELSG fuses are interchangeable with the K-MATE™ SL (A.B. Chance) assembly. ELSG fuses have been tested and meet all requirements set forth in IEEE Std C37.40™, IEEE Std C37.41™ and

IEEE Std C37.46™ standards.

X-Limiter™ hinge-mount fuses |

|

||

GENERALThe Cooper Power Systems Combined Technologies (CT)X-Limiter™ hinge-mount fuses are designed to fit the mountings manufactured by S & C Electric Company. The X-Limiter hinge-mount fuses are full-range, current-limiting fuses to be used indoors or for metal clad applications, and outdoors for cross-arm mounting or substation mounting, for the following S & C Electric Company mountings: |

|||

|

|||

The availability of the X-Limiter hinge-mount fuse makes it easy to convert from expulsion fuses directly to a full-range, current-limiting fuse in the same mounting. The designs utilize the S & C standard end fittings

(hinge-end and latched-end) to ensure a perfect fit in the mountings.

APPLICATION

X-Limiter hinge-mount fuses are rated at phase-to-ground voltage. This is an acceptable practice when:

|

||

X-Limiter™ Unitized fuse |

|

GENERALThe Cooper Power Systems Combined Technologies (CT) X-Limiter™ Unitized fuse allows paralleling the two-inchdiameter 4.3 kV, 5.5 kV, 8.3 kV and 15.5 kV fuses to fit the NX® Code 1 and Code 2 hinge mountings. It provides double current rated fused switching when a loadbreak feature is not required. The X-Limiter Unitized fuse has the same electrical characteristics and follows the same application criteria as the X-limiter fuse, described in Catalog Section 240-56. One operation indicator is included per fuse set. |

ELX Full Range Current-Limiting Fuse

GENERAL

The ELX fuse is a full range current limiting fuse designed to provide overcurrent protection. It is completely interchangeable with similar fuses using industry standard clip-style and dry well canister mountings. Quiet, safe operating characteristics of the ELX fuse make it ideal for installations where flame discharge and loud operation are undesirable.

Typical applications include clip mounting air-insulated apparatus, padmounted equipment sectionalizing enclosures, metal clad switchgear and industrial vaults. Since the ELX fuse has no gas-evolving parts, it is ideal for use in dry well canisters. This fuse is also used in field refusible bushings, such as those used on pole-type and live front pad-mounted transformers. Both deadbreak and loadbreak dry well canister manufactured by Cooper Power Systems, General Electric, Westinghouse, and Kuhlman can be re-fused using the ELX fuse.

X-Limiter Full Range Current-Limiting Fuse |

|

| GENERAL Cooper Power Systems X-Limiter fullrange current-limiting fuses are used for transformer protection, capacitor protection and sectionalizing. Their non-gas evolving element design allows for maximum energy limitation and minimum peak arc voltages without corrosive by-products. Thus, they can significantly limit the electrical and mechanical stresses on the protected equipment and the whole system supplying the fault. The X-Limiter is tested to meet ANSI/IEEE Standard design requirements for power fuses as well as distribution class fuses. |

X-Limiter Clip Style Fuses

The X-Limiter fuse’s patented element design allows a “tailored” time current curve and superior full-range clearing characteristics. This ensures easy coordination with upstream and downstream protective equipment such as “C”, “E”, “K”, or “T” rated fuses. The X-Limiter current-limiting fuses have the ability to interrupt any current which will melt its element, from its minimum melt rating through its maximum interrupting rating. In most

applications it does not require derating in elevated temperature environments. For applications requiring higher load capacity, X-Limiter fuses can be used in parallel to double current ratings.

X-Limiter Unitized Fuse

The X-Limiter unitized fuse allows paralleling the two-inch diameter 4.3 kV, 5.5 kV, 8.3 kV and 15.5 kV fuses to fit Code 1 and Code 2 hinge mountings. It provides double current rated fused switching when a loadbreak feature is not required. The X-Limiter unitized fuse has the same electrical characteristics and follows the same application criteria as the X-Limiter clip- and hinge-style fuses. One operation indicator per fuse set is included.

INSTALLATION

The X-Limiter fuse is designed to fit industry standard mountings. Each fuse is marked with its mounting code number (either 1, 2, 4, 5, 6 or 9). The mounting code number defines the mounting’s insulation level, contact spacing, and contact type.

X-Limiter clip-style fuses fit 5/8” standard clip-style mountings in padmounted transformers, switchgear, sectionalizing enclosures, industrial vaults and metal clad switchgear. They also fit drywell canisters, both deadbreak and loadbreak. In single drywell canister applications the X-Limiter fuse can provide continuous load current capability through 50 A.

Parallel drywell applications provide capability through 100 A. The X-Limiter hinge-style fuse fits the standard

hinge-style mountings in overhead applications.

ELF-LR™ Current-Limiting Fuse |

|

GENERALThe Cooper Power Systems ELF-LR™ Current-Limiting Fuse is a full range current-limiting fuse that is suitable foruse in areas where a high-fire hazard exists. ELF-LR liquid fuse replacements are noiseless and expel no hot gases or burning particles while performing fault current interruptions. |

The ELF-LR fuse has been granted permanent exemption by the California Dept. of Forestry and Fire Protection

from the pole clearance requirements when mounted in the field according to manufacturer’s specifications. ELF-LR fuses are designed to protect pole-type transformers, single-phase and three-phase laterals and underground taps.

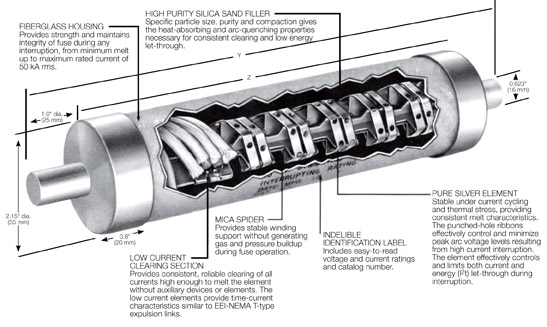

The full range current-limiting rating ensures reliable operation of all overloads and fault currents. The element construction consists of two separate sections (low-current section and high-current section) which are self-contained in one housing. The low-current section provides consistent, reliable clearing of all currents high

enough to melt the element. The high-current section is a punched-hole ribbon design that controls peak arc

voltage levels and limits both current and energy (I2t) let-through levels during high-current fault clearing

operation.

PRODUCTION TESTS

Tests are conducted on 100% of production in accordance with Cooper Power Systems requirements.

■ Physical Inspection

■ I2t Testing

■ Resistance Testing

■ Helium Mass Spectrometer Leak Testing

Back to top

For additional information on McGraw Edison Fuses contact us at 918.665.6888, or use our fuse search tab at the top of the page. You can also request a quote on any of the McGraw Edison Fuses using our quote form.